PRO™ Variable Speed Control

PPC820 Proportional Power Controller

-

PRO - VARIABLE SPEED CONTROL

A PRO thruster system with variable speed control allows for more precise handling of the boat in all conditions, applying only the necessary power needed to complete your maneuver confidently.

By limiting the power under normal weather conditions, noise levels are significantly reduced. The system also includes a practical hold-function in a twin thruster system. With a single press of a button, the bow and stern thruster will keep you alongside the docks - making docking truly a one-person job. PRO thrusters are the best choice for joystick interaction.

A PRO system contains three main elements - a control panel, a power control unit, and a DC electric thruster - all tied together with the S-link™ control system. All mechanical and main electric parts are from the well-proven thruster range produced by Sleipner for many years.

All of Sleipner's 12 and 24 volt DC electric thrusters can be enabled for variable speed control by authorized Sleipner service personnel, even past models.

-

S-LINK™

S-Link™ is a CAN-based control system with full intelligent communication between all units in the system, much like a computer network.

- Round, compact and waterproof connectors with unique keying and color coding to avoid faulty hookup

- Unlimited number of commands or information transferred on a single cable

- User feedback on the panel

- Intelligent troubleshooting

Codice Articolo: PPC820

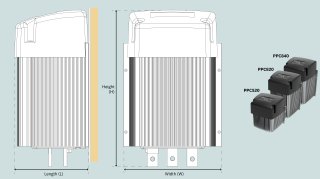

The PPC820 Power Control Unit rates for a maximum output current of 1000A and is compatible with all 12-volt and 24-volt electric thrusters.

The PPC820 store historical fault codes and communicate real-time information to the PJC control panel such as amount and direction of thrust on either thruster, remaining run time, battery status and temperature.

Please note that the PJC control panels must be running software v2.018 or later to support these new units.

To upgrade a standard on/off thruster system to PRO (variable speed control), you need a PPC Power Control Unit and an upgrade kit for the internal wiring loom. Your local Sleipner dealer can advise correct upgrade kits for your system.

PPC820 Power Control Unit

- Plug & Play S-Link™ control cable wiring

- Easy to access, solid main cable terminals

- Reliable solid-state switching

- Thermal and over current protection

- Active cooling for continuous usage

Thruster Compatibility

| 12V | All models |

| 24V | All models |

| 48V | Not supported |

Caratteristiche

PRO - VARIABLE SPEED CONTROL

A PRO thruster system with variable speed control allows for more precise handling of the boat in all conditions, applying only the necessary power needed to complete your maneuver confidently.

By limiting the power under normal weather conditions, noise levels are significantly reduced. The system also includes a practical hold-function in a twin thruster system. With a single press of a button, the bow and stern thruster will keep you alongside the docks - making docking truly a one-person job. PRO thrusters are the best choice for joystick interaction.

A PRO system contains three main elements - a control panel, a power control unit, and a DC electric thruster - all tied together with the S-link™ control system. All mechanical and main electric parts are from the well-proven thruster range produced by Sleipner for many years.

All of Sleipner's 12 and 24 volt DC electric thrusters can be enabled for variable speed control by authorized Sleipner service personnel, even past models.

S-LINK™

S-Link™ is a CAN-based control system with full intelligent communication between all units in the system, much like a computer network.

- Round, compact and waterproof connectors with unique keying and color coding to avoid faulty hookup

- Unlimited number of commands or information transferred on a single cable

- User feedback on the panel

- Intelligent troubleshooting

-

A legacy that commits

We’ve lived and worked with the unruly sea for a hundred years. That’s why we develop important features that enables a boat to handle the sea better – that enable you to enjoy your boat, at anchor and at full speed. That is why you wanted a boat, isn’t it?

-

Beautiful engineering

The technology in our solutions is world-class. We know, because we’ve developed it ourselves, just as we manufacture every solution, and follow them until their fixed to a hull, ourselves. This meticulous attention to detail is why your day out always will be better with a Sleipner aboard.

-

Worldwide service

We take pride in our solutions’ function throughout their lifespan. So, we never really let them out of sight, even when they’ve left for distant shores. Our global network is there to ensure continuous optimal function. You know what you get with a Sleipner, today and tomorrow.