- Home

- Eliche di manovra

- Eliche di manovra

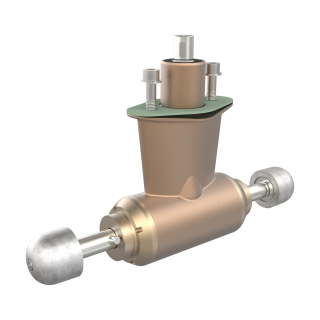

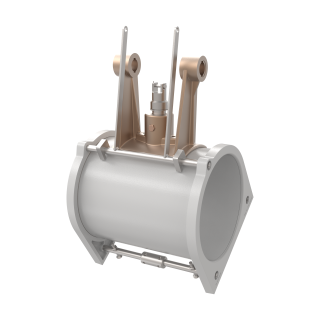

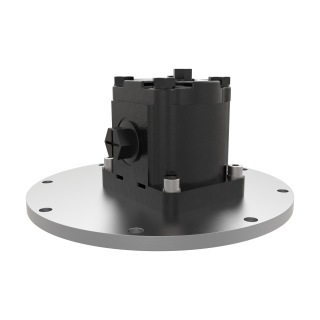

- SRHP320 Elica di manovra retrattile idraulica per prua/poppa

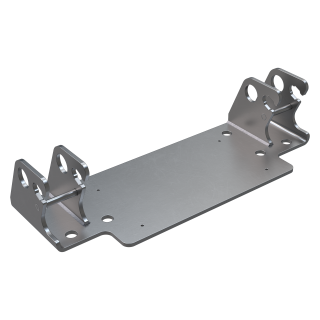

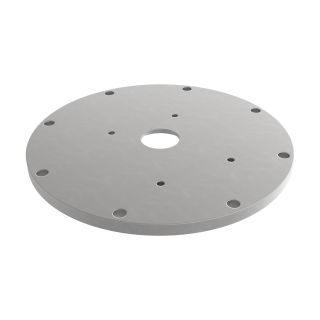

Unless you vessel is prepared from the builder with a custom base, you will need the mold-in base for installing your retract.

Eliche di manovra

SRHP320 Elica di manovra retrattile idraulica per prua/poppa

320kg thrust, 16cm³

-

PRO - VARIABLE SPEED CONTROL

A PRO thruster system with variable speed control allows for more precise handling of the boat in all conditions, applying only the necessary power needed to complete your maneuver confidently.

By limiting the power under normal weather conditions, noise levels are significantly reduced. The system also includes a practical hold-function in a twin thruster system. With a single press of a button, the bow and stern thruster will keep you alongside the docks - making docking truly a one-person job. PRO thrusters are the best choice for joystick interaction.

A PRO system contains three main elements - a control panel, a power control unit, and a DC electric thruster - all tied together with the S-link™ control system. All mechanical and main electric parts are from the well-proven thruster range produced by Sleipner for many years.

All of Sleipner's 12 and 24 volt DC electric thrusters can be enabled for variable speed control by authorized Sleipner service personnel, even past models.

-

S-LINK™

S-Link™ is a CAN-based control system with full intelligent communication between all units in the system, much like a computer network.

- Round, compact and waterproof connectors with unique keying and color coding to avoid faulty hookup

- Unlimited number of commands or information transferred on a single cable

- User feedback on the panel

- Intelligent troubleshooting

-

Q-PROP™

The 5 blade special skew propellers are designed to reduce noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust by 5%. Please see individual information on your preferred thruster model for more details.

- Noise reductions of up to 75% measured in controlled environments

- The expected and tested normal noise reduction in average installations: 20-40%

- Upgrade kits are available for most Side-Power thrusters with special adaptors

-

SEALED DRIVE LUBRICATION

Sealed gearleg with long-life "mechanical" seal where highly polished ceramic and carbon surfaces form the only moving sealing surfaces, ensuring protection against damaging water intrusion into the gear leg. Pre-filled with special gear oil for lifetime lubrication.

- "Mechanical" seals with surfaces of ceramic and carbon for ultimate security against water intrusion

-

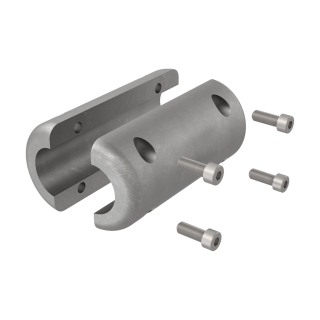

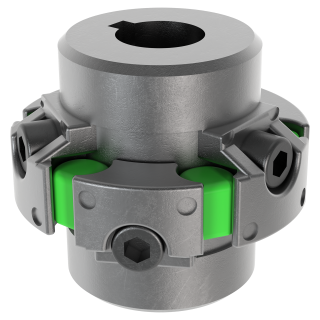

FLEXIBLE COUPLING

Flexible coupling between electronic motor and driveshaft protects both the electronic motor and gear systems if the propeller jams or obstructs.

-

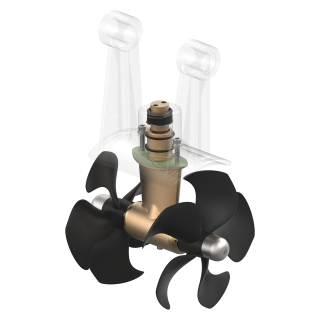

TWIN COUNTER-ROTATING PROPELLERS

Two counter-rotating propellers can give the most thrust at a good performance ratio in a minimal tunnel diameter. This system is used in our larger thrusters for maximum power. The TC models are the favourite thrusters among leading boatbuilders for their high-end yachts.

Codice Articolo: SRHP320/300TC-G16

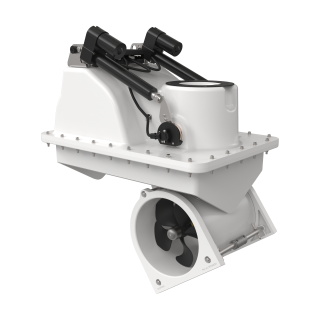

The SRHP320 is a sturdy hydraulic retractable thruster suitable for cruiser-racers or flat-bottomed boats between 72-110 feet/ 22-34 meters. With its quick deployment, 320 kgs of thrust, and variable speed control, all you need to worry about when docking is getting the ropes ready.

Read more about the significant product features below.

Caratteristiche

PRO - VARIABLE SPEED CONTROL

A PRO thruster system with variable speed control allows for more precise handling of the boat in all conditions, applying only the necessary power needed to complete your maneuver confidently.

By limiting the power under normal weather conditions, noise levels are significantly reduced. The system also includes a practical hold-function in a twin thruster system. With a single press of a button, the bow and stern thruster will keep you alongside the docks - making docking truly a one-person job. PRO thrusters are the best choice for joystick interaction.

A PRO system contains three main elements - a control panel, a power control unit, and a DC electric thruster - all tied together with the S-link™ control system. All mechanical and main electric parts are from the well-proven thruster range produced by Sleipner for many years.

All of Sleipner's 12 and 24 volt DC electric thrusters can be enabled for variable speed control by authorized Sleipner service personnel, even past models.

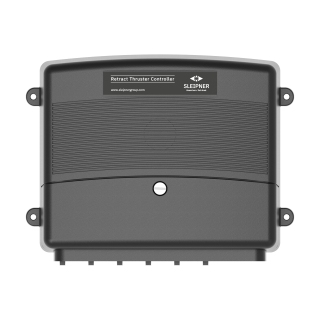

S-LINK™

S-Link™ is a CAN-based control system with full intelligent communication between all units in the system, much like a computer network.

- Round, compact and waterproof connectors with unique keying and color coding to avoid faulty hookup

- Unlimited number of commands or information transferred on a single cable

- User feedback on the panel

- Intelligent troubleshooting

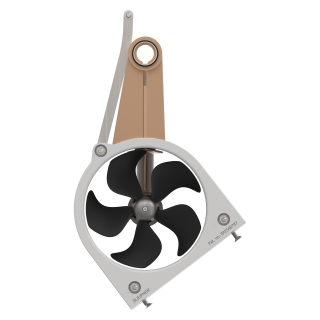

Q-PROP™

The 5 blade special skew propellers are designed to reduce noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust by 5%. Please see individual information on your preferred thruster model for more details.

- Noise reductions of up to 75% measured in controlled environments

- The expected and tested normal noise reduction in average installations: 20-40%

- Upgrade kits are available for most Side-Power thrusters with special adaptors

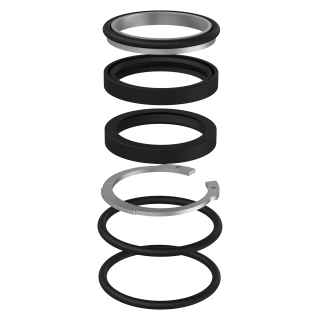

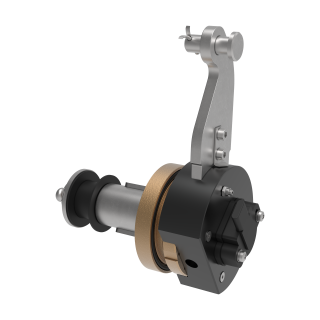

SEALED DRIVE LUBRICATION

Sealed gearleg with long-life "mechanical" seal where highly polished ceramic and carbon surfaces form the only moving sealing surfaces, ensuring protection against damaging water intrusion into the gear leg. Pre-filled with special gear oil for lifetime lubrication.

- "Mechanical" seals with surfaces of ceramic and carbon for ultimate security against water intrusion

FLEXIBLE COUPLING

Flexible coupling between electronic motor and driveshaft protects both the electronic motor and gear systems if the propeller jams or obstructs.

TWIN COUNTER-ROTATING PROPELLERS

Two counter-rotating propellers can give the most thrust at a good performance ratio in a minimal tunnel diameter. This system is used in our larger thrusters for maximum power. The TC models are the favourite thrusters among leading boatbuilders for their high-end yachts.

| Main power | Valore |

|---|---|

| Power supply | Idraulico |

| Alarms | Valore |

|---|---|

| Alarm notification | Via the product's control device |

| Thrust ratings | Valore |

|---|---|

| At heavy duty thrust | 270kg / 595.25lbs |

| At light duty thrust | 320kg / 705.48lbs |

| Features | Valore |

|---|---|

| Q-Propeller | Si |

| Twin Counter Rotating Propellers | Si |

| Sealed Drive Lubrication | Si |

| PRO - Variable Speed Control | Si |

| S-Link | Si |

| Flexible Coupling | Si |

| Physical properties | Valore |

|---|---|

| Thruster Series | SR-series |

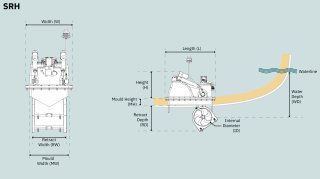

| Dimensions | Valore |

|---|---|

| (H) Altezza | 455mm / 17.91in |

| (L) Lunghezza | 843mm / 33.19in |

| (+L) Lunghezza addizionale | 12mm / 0.47in |

| (W) Larghezza | 580mm / 22.83in |

| (ID) Diametro interno | 300mm / 11.81in |

| (WD min.) Minimum Water Depth | 300mm / 11.81in |

| (RD) Profondità retraibile | 445mm / 17.52in |

| (RW) Larghezza retraibile | 415mm / 16.34in |

| Installation capability | Valore |

|---|---|

| Possibilità utilizzo a prua | Si |

| Possibilità utilizzo a poppa | Si |

| Possibilità ad essere retraibile | Si |

| Idraulico | Valore |

|---|---|

| Shock valve | Si |

| Port specifications | Valore |

|---|---|

| Port A/B | 22L, Metric DIN 2353 |

| Drain port | 1/4" BSP |

| Flow rates | Valore |

|---|---|

| 60% Flow rate | 32L/min / Nonenull |

| 80% Flow rate | 36.9L/min / Nonenull |

| 100% Flow rate | 41.3L/min / Nonenull |

| Pressure rates | Valore |

|---|---|

| 60% Pressure rate | 152Bar / Nonenull |

| 80% Pressure rate | 202Bar / Nonenull |

| 100% Pressure rate | 253Bar / Nonenull |

| Ideal vessel integration | Valore |

|---|---|

| Typical vessel class | Barca a motore, Barca a vela |

| Typical vessel size | 22-34m / 72.18-111.55ft |

| Product weight | Valore |

|---|---|

| Net weight | 88kg / 194.01lbs |

-

DNV AiP Thruster retract composite housing SR Ø250 and Ø300

Conformity CertificateInglesepdf -

Joystick integration overview for Sleipner thruster systems

Service/Support ManualInglesepdf -

PDF.fil SRHP320/300TC-Gxx Hyd. retract thruster - MetaData

Technical drawingInglesepdf -

STP.fil SRHP320/300TC-Gxx Retract - open thruster Hydraulic

CAD FileInglesestp -

XT.file SRHP320/300TC-Gxx Retract - closed thruster - simplified

CAD FileInglesex-t -

XT.file SRHP320/300TC-Gxx Hyd. open retract thruster

CAD FileInglesex-t -

STP.fil SRHP320/300TC-Gxx Retract - closed thruster - simplified

CAD FileInglesestp -

User Manual, SRH Pro (SRHP)

User ManualInglesepdf -

Installation Manual, SRHP (240, 320)

Installation ManualInglesepdf

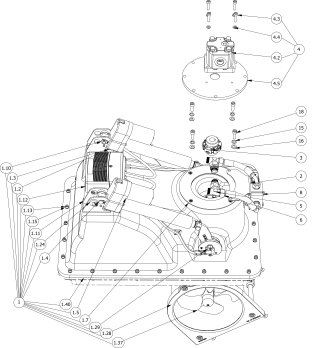

SRHP320 Elica di manovra retrattile idraulica per prua/poppa

Guida alla navigazione dei pezzi di ricambio

Di seguito vedrai l'assemblaggio di alto livello delle unità di ricambio a tua disposizione. Se desideri un componente all'interno dell'unità presentata, fai clic sull'etichetta del nome sotto l'immagine per essere indirizzato a un elenco dettagliato dei pezzi di ricambio per quell'unità. Se non sono disponibili pezzi di ricambio aggiuntivi, significa che l'unità attuale deve essere acquistata nel suo insieme per esigenze di servizio o installazione.

Hyd. motor 16 ccm

Cutting ring fitting

Hydr connection

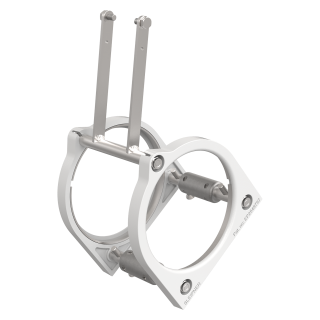

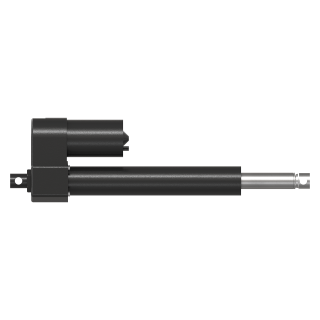

1 Retract Mechanical

DIN 912 - M4 x 12

Cable actuator

DIN 125 - A 13

DIN EN ISO 1234 - 3,2x20

Locking bolt

DIN 913 - M4 x 20

DIN 985 - M4x0,7

M4 x 25 A4

DIN 127 - A 4

DIN 125 - A 4,3

ISO 10642 - M4 x 30

Cable SRV/SRH 300

2 Retract Horizontal Shaft Kit - 300mm

DIN 7991 - M4x12 A4

Parallel key DIN 6885

Lifting arm PS

DIN 125 - A 29

Lifting arm SB

Position marker

DIN 912 - M5 x 8

3 Vertical drive shaft kit

DIN 912 - M6 x 20

DIN 125 - A 6,4

Tool for ball bearing mounting

DIN 471 - 25x1,2

SKF 2RS1W 61805-2RS1

DIN 472 - 35 x 1,5

Rotary lip seal

Slide bearing

Vertical drive shaft Assembly

DIN EN ISO 1234 - 3,2x12

Lower drive shaft joint

DIN 7 - 10 x 32 m6

DIN 6885 - A 6 x 6 x 20

Pin Ø8 L46,2

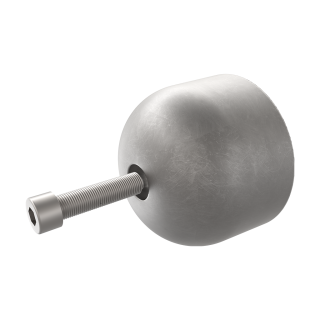

4 Anodo alluminio per SE120/130/150/170

Anode - aluminium

Hex socket cap screw

5 Tunnel kit retract Ø300mm TC, complete

DIN EN ISO 1234 - 3,2x20

DIN 3771 - 48,9 x 2,62 - NBR

Turn ring Ø45

Wype Ring

Tunnel bracket

DIN EN ISO 1234 - 6,3x44

DIN EN ISO 1234 - 3,2x12

Ø8 x 46,2 mm

Lower drive shaft joint

DIN 7 - 10 x 32 m6

O-ring 12,5 x 1,8

Blind plug

Tunnel

Bushing for drive pins

6 Horizontal shaft sealing bushing kit

DIN EN ISO 1234 - 3,2x20

Sleeve bearing Ø50 ø45 L50

DIN 3771 - 48,9 x 2,62 - NBR

Turn ring Ø45

Wype Ring

Sleeve bearing Ø32 Ø28 L20

Thrust Washer Ø48 Ø28 W=1,5 8Igludur X)

DIN EN ISO 1234 - 6,3x44 (A4)

Pin Ø8 L46,2

DIN EN ISO 1234 - 3,2x12 (A4)

7 Kit anello per retrattile Ø300mm

Sleeve bearing

Thrust washer

DIN 933 - M10 x 20 (A4)

DIN 934 - M10 (A4)

DIN 7991 - M10x70 A4

Connecting rod

Twist ring

DIN 125 - A 10,5 (A4)

DIN 985 - M10x1,5 (A4)

8 Kit sostituzione piede per SRV300

Bushing for drive pins

9 Piede elica di manovra senza elica SRV300TC

DIN 912 - M10 x 60

DIN 127 - A 10

DIN 125 - A 10,5

Bolt w/copper gasket

DIN 125 - A 17

DIN 985 - M16x2

10 Kit service per 300mm

Wyper ring

O-ring 41,28x3,53

DIN 3760 - AS - 40 x 50 x 7 - NBR - Stainless

Inverted Internal Circlip DIN 5008 50x2

O-ring Ø50x4

Esclusione di Responsabilità

Sleipner garantisce unicamente i ricambi originali forniti. L'installatore è il solo responsabile dell'installazione dei ricambi. Non tentare l'installazione di ricambi se non avete le competenze. Se il pezzo di ricambio è montato in modo errato, Sleipner Group non sarà responsabile per eventuali danni che ne derivano.

Le informazioni fornite nel documentazione erano corrette al momento della pubblicazione. Tuttavia, Sleipner Group non si assume alcuna responsabilità per eventuali inesattezze o omissioni in esso contenute. Il miglioramento continuo del prodotto può modificare le specifiche del prodotto senza preavviso. Di conseguenza, Sleipner Group declina ogni responsabilità per eventuali differenze tra prodotto e documentazione.

-

S-link è un sistema di controllo Sleipner basato su CANbus con comunicazione completamente intelligente tra tutti i dispositivi all'interno del sistema, proprio come una rete di computer. Viene utilizzato per tutti i propulsori retrattili e i propulsori Pro con un sistema di controllo in DC.

I principali vantaggi includono:

- Ha connettori rotondi e compatti ed ha connessioni impermeabili con inserimento univoco e codifica a colori per evitare errori nei collegamenti;

- Può gestire un numero illimitato di comandi o trasferimento di informazioni su un singolo cavo;

- Ha il feedback del sistema sul pannello utente;

- Incorpora la diagnostica avanazata.

-

A legacy that commits

We’ve lived and worked with the unruly sea for a hundred years. That’s why we develop important features that enables a boat to handle the sea better – that enable you to enjoy your boat, at anchor and at full speed. That is why you wanted a boat, isn’t it?

-

Beautiful engineering

The technology in our solutions is world-class. We know, because we’ve developed it ourselves, just as we manufacture every solution, and follow them until their fixed to a hull, ourselves. This meticulous attention to detail is why your day out always will be better with a Sleipner aboard.

-

Worldwide service

We take pride in our solutions’ function throughout their lifespan. So, we never really let them out of sight, even when they’ve left for distant shores. Our global network is there to ensure continuous optimal function. You know what you get with a Sleipner, today and tomorrow.

-1.png)