Eliche di manovra

SE100 Elica di manovra per tunnel prua/poppa, 24V

100kg thrust, on/off

-

INTELLIGENT POWER CONTROL

The Sleipner unique thruster controller that intelligently protects the thruster from potential inherent problems in all high current applications as well as user faults. It includes several important safety features imperative in a product with such high power, run by DC electrics, as a thruster.

- Provides delay between drive directions

- Monitors solenoid functions to reduce the chance of solenoid lock-in

- Will stop the thruster in case of a lockedin solenoid, without extra user action and even without controlling a main switch.

-

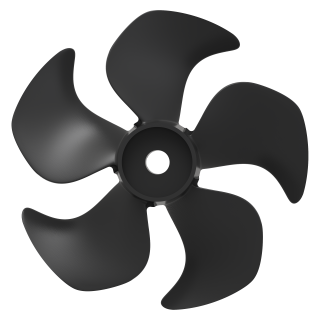

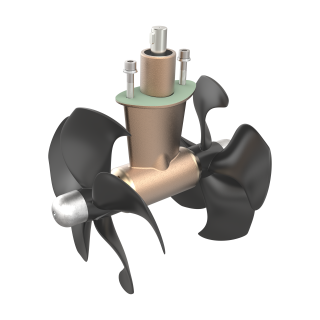

Q-PROP™

The 5 blade special skew propellers are designed to reduce noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust by 5%. Please see individual information on your preferred thruster model for more details.

- Noise reductions of up to 75% measured in controlled environments

- The expected and tested normal noise reduction in average installations: 20-40%

- Upgrade kits are available for most Side-Power thrusters with special adaptors

-

OVERHEAT PROTECTION

Detect when internal components become too hot. When an unsafe temperature is detected, the switch automatically shuts off the unit to prevent overheating.

-

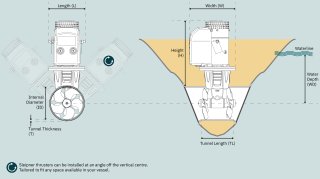

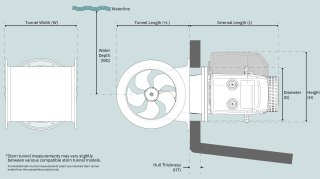

FLEXIBLE INSTALLATION

Our Thrusters are designed to allow installation at any angle on the tunnel and the motor at various rotations on the bracket. The installation flexibility for our thruster systems is created to work with the space you have! not the space you need.

-

ANALOG

Sleipner analog signal cables with plug-and-go connectors are color-coded to match the wiring diagrams with high-quality connectors to ensure a correct installation.

-

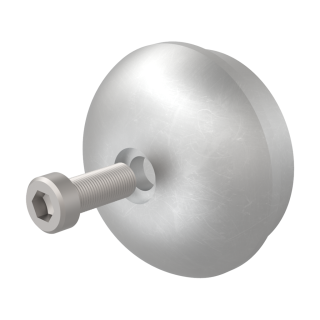

GALVANIC SEPARATION

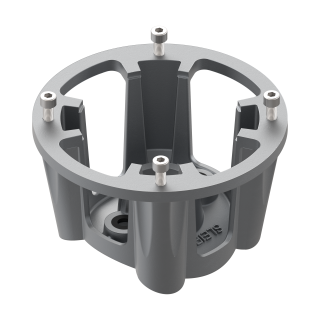

The gear house and drive legs are fully galvanically isolated/separated from the electric motor and motor bracket. This ensures that even if there is an accidental short circuit or a current leak for other reasons, the immersed parts are not affected as they could be with direct electric contact.

- Achieved by composite bushings around the bolts and beneath the washers and a bushing in the motor bracket electrically isolating the drive housing from the motor bracket.

- Available on DC electric models with flexible couplers only, where the flexible coupler provides galvanic separation of the motor and gearleg shaft.

-

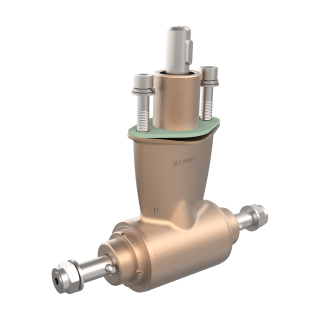

SEALED DRIVE LUBRICATION

Sealed gearleg with long-life "mechanical" seal where highly polished ceramic and carbon surfaces form the only moving sealing surfaces, ensuring protection against damaging water intrusion into the gear leg. Pre-filled with special gear oil for lifetime lubrication.

- "Mechanical" seals with surfaces of ceramic and carbon for ultimate security against water intrusion

-

FLEXIBLE COUPLING

Flexible coupling between electronic motor and driveshaft protects both the electronic motor and gear systems if the propeller jams or obstructs.

-

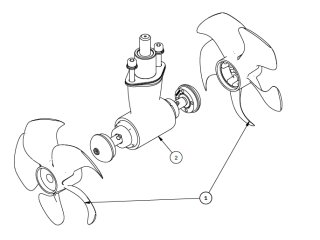

TWIN PROPELLERS

The twin propeller system can give more thrust than a single propeller system in the same tunnel diameter. This is our choice for our mid-range models where high thrust is required in a small tunnel diameter. Due to the compact design and high performance, the twin models have become the thrusters of choice among boat builders around the world.

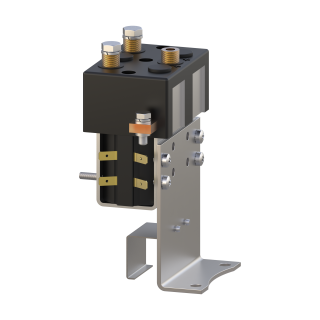

Codice Articolo: SE100/185T-24V

The SE100 is the most powerful thruster available in the popular 185mm tunnel diameter and is thereby the optimal choice for boats between 35-55 feet where maximum thrust in a compact tunnel is required. With its 100-116 kgs of thrust, you get a reliable thruster when you need it the most.

Also available in PRO with variable speed control. Remote control is a popular accessory. Read more about the significant product features below.

Caratteristiche

INTELLIGENT POWER CONTROL

The Sleipner unique thruster controller that intelligently protects the thruster from potential inherent problems in all high current applications as well as user faults. It includes several important safety features imperative in a product with such high power, run by DC electrics, as a thruster.

- Provides delay between drive directions

- Monitors solenoid functions to reduce the chance of solenoid lock-in

- Will stop the thruster in case of a lockedin solenoid, without extra user action and even without controlling a main switch.

Q-PROP™

The 5 blade special skew propellers are designed to reduce noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust by 5%. Please see individual information on your preferred thruster model for more details.

- Noise reductions of up to 75% measured in controlled environments

- The expected and tested normal noise reduction in average installations: 20-40%

- Upgrade kits are available for most Side-Power thrusters with special adaptors

OVERHEAT PROTECTION

Detect when internal components become too hot. When an unsafe temperature is detected, the switch automatically shuts off the unit to prevent overheating.

FLEXIBLE INSTALLATION

Our Thrusters are designed to allow installation at any angle on the tunnel and the motor at various rotations on the bracket. The installation flexibility for our thruster systems is created to work with the space you have! not the space you need.

ANALOG

Sleipner analog signal cables with plug-and-go connectors are color-coded to match the wiring diagrams with high-quality connectors to ensure a correct installation.

GALVANIC SEPARATION

The gear house and drive legs are fully galvanically isolated/separated from the electric motor and motor bracket. This ensures that even if there is an accidental short circuit or a current leak for other reasons, the immersed parts are not affected as they could be with direct electric contact.

- Achieved by composite bushings around the bolts and beneath the washers and a bushing in the motor bracket electrically isolating the drive housing from the motor bracket.

- Available on DC electric models with flexible couplers only, where the flexible coupler provides galvanic separation of the motor and gearleg shaft.

SEALED DRIVE LUBRICATION

Sealed gearleg with long-life "mechanical" seal where highly polished ceramic and carbon surfaces form the only moving sealing surfaces, ensuring protection against damaging water intrusion into the gear leg. Pre-filled with special gear oil for lifetime lubrication.

- "Mechanical" seals with surfaces of ceramic and carbon for ultimate security against water intrusion

FLEXIBLE COUPLING

Flexible coupling between electronic motor and driveshaft protects both the electronic motor and gear systems if the propeller jams or obstructs.

TWIN PROPELLERS

The twin propeller system can give more thrust than a single propeller system in the same tunnel diameter. This is our choice for our mid-range models where high thrust is required in a small tunnel diameter. Due to the compact design and high performance, the twin models have become the thrusters of choice among boat builders around the world.

-

A legacy that commits

We’ve lived and worked with the unruly sea for a hundred years. That’s why we develop important features that enables a boat to handle the sea better – that enable you to enjoy your boat, at anchor and at full speed. That is why you wanted a boat, isn’t it?

-

Beautiful engineering

The technology in our solutions is world-class. We know, because we’ve developed it ourselves, just as we manufacture every solution, and follow them until their fixed to a hull, ourselves. This meticulous attention to detail is why your day out always will be better with a Sleipner aboard.

-

Worldwide service

We take pride in our solutions’ function throughout their lifespan. So, we never really let them out of sight, even when they’ve left for distant shores. Our global network is there to ensure continuous optimal function. You know what you get with a Sleipner, today and tomorrow.

@72dpi.png)